Introduction

MISE À JOUR 06/06/18 Quelqu'un fabrique une pièce de rechange ! Masica, merci pour le tuyau! Cherchez sur eBay "arbre DS-560" et il est venu tout de suite du vendeur g_loc.

Pour la solution de contournement, vous n'avez besoin que d'une agrafe, pliée droite ou d'une épingle droite. Pour la réparation avec un trombone, vous aurez besoin de deux très petits tournevis à tête plate pour faire levier et d'un tournevis à tête Philips normal et d'une paire de pinces ou deux. Vous allez retirer les coques extérieures des deux pièces du corps principal, retirer un petit arbre et plier un trombone autour de l'arbre pour le remettre fermement en place.

LE PROBLÈME : Dans la section avant que vous tirez sur le levier gris pour permettre de pivoter d'environ 30 degrés -- c'est la section qui indique Epson à l'avant et qui a les lumières -- une pièce s'est détériorée là-dedans. Voici l'essentiel : pour tirer une seule feuille à la fois, les rouleaux du panneau avant ne doivent pas bouger jusqu'à la dernière feuille ; ils créent une friction lorsque le scanner tire les feuilles en dessous. Ce qui s'est passé, c'est qu'une pièce censée empêcher le rouleau de bouger a échoué et le rouleau roule maintenant et donc toute la pile passe. Un petit arbre en plastique a des languettes qui se sont évasées à une extrémité et ne maintiendront pas les rouleaux en place.

Il devrait être facilement remplaçable - presque sans démontage, mais les schémas de pièces Epson ne montrent pas cette pièce séparément, donc je n'ai pas trouvé d'endroit pour en acheter une nouvelle.

Outils

-

-

Cette première étape est une solution de contournement, le guide de réparation commence à l'étape QUATRE. Utilisez-le si vous êtes désespéré et en avez absolument besoin pour numériser des centaines de pages MAINTENANT. Ouvrez le panneau avant en tirant le levier gris comme indiqué.

-

REMARQUE : Une personne a indiqué que cela fonctionnait pour eux sans que cela se bloque et qu'il s'agit donc de leur solution permanente, alors essayez ceci en premier.

-

Allez directement aux rouleaux et retirez-les, puis suivez le retrait de l'arbre tronqué pour votre réparation. L'assemblage a nécessité que le DS-510 soit placé sur le côté regardant vers le bas dans le trou d'accès et assurez-vous que l'arbre intérieur est là pour s'engager et terminer l'assemblage et réinstaller les rouleaux."

-

-

-

À l'intérieur, au dos du panneau que vous venez d'ouvrir, vous verrez deux rouleaux en mousse identiques. Collez une agrafe redressée ou une épingle droite à travers la mousse afin qu'ils ne puissent plus rouler une fois que l'épingle touche la barre entre eux. REMARQUE : Une personne a indiqué que cela fonctionnait pour eux sans que cela se bloque

-

-

-

Lorsque vous allez numériser de cette façon, vous devrez mettre une feuille supplémentaire à la fin de votre pile qui se "bloquera" une fois qu'elle essaiera de numériser, car les rouleaux ne la lâcheront pas, mais vous au moins numériser le reste des papiers.

-

-

-

LA RÉPARATION : Il y a 4 vis sur le couvercle du panneau avant que nous devons retirer, mais elles ne sont pas accessibles tant que vous n'avez pas retiré tout ce panneau du corps principal du scanner. Les vis les plus proches de l'endroit où il s'articule sont celles qui sont difficiles à retirer.

-

Si vous avez un cliquet à profil très bas, vous pourrez peut-être accéder aux quatre sans avoir à retirer le panneau avant. Si c'est le cas, passez directement à l'étape 7.

-

-

-

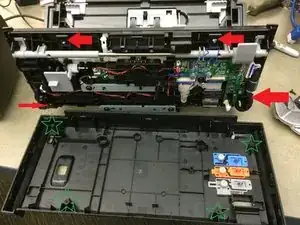

Les trois vis au bas du corps principal - vous devrez étendre complètement le plateau pour accéder à l'une d'entre elles. Ensuite, il y a trois autres vis au-dessus, sur la face principale du scanner, où vous placez les feuilles à numériser. L'un se trouve sous le rouleau remplaçable, les deux derrière les curseurs de largeur de papier gris

-

-

-

Il y a une troisième vis à l'avant de la base qui est difficile à atteindre même avec le plateau poussé à fond vers l'avant.

-

Vous pouvez retirer complètement la base en la faisant glisser vers l'avant et en soulevant les deux grands clips de chaque côté.

-

Cela facilite l'accès à la troisième vis à l'avant de la base.

-

-

-

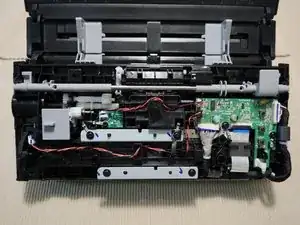

Tirez le corps principal du scanner hors de sa coque enveloppante, en utilisant un petit outil de levier pour aider à faire sortir la coque sur les bords. C'est du plastique résistant, donc vous ne casserez rien, et c'est surtout creux aussi, alors ne vous inquiétez pas de l'endroit où le tournevis va à l'intérieur pendant que vous faites levier.

-

On voit ici la coquille une fois que les "tripes" en sont sorties.

-

-

-

vous devrez retirer une vis de chaque côté pour les charnières du panneau avant et ils ont tous les deux de petits couvercles à enlever aussi.

-

-

-

Le panneau latéral emprisonne le faisceau électrique et interfère avec le glissement du panneau avant hors de ses charnières.

-

Le retrait du panneau latéral facilite grandement le glissement du panneau avant hors de ses charnières.

-

Cela laisse beaucoup de harnais lâche pour poser le panneau avant face vers le bas à côté de la base.

-

-

-

Soulevez le panneau avant à environ 45 degrés ou jusqu'à ce que vous puissiez le faire glisser complètement vers la gauche.

-

Cela vous permet de soulever la charnière droite hors de l'encoche de la charnière, comme indiqué sur l'image.

-

Vous pouvez ensuite faire glisser l'ensemble du panneau vers la droite et il le fera glisser hors de la charnière gauche.

-

-

-

Retirez les quatre vis et utilisez un petit outil plat pour faire sortir le couvercle du panneau. La barre grise qui court à l'intérieur, qui comporte le levier pour ouvrir le panneau - à cause de ses ressorts, vous devez la maintenir attachée au panneau et NON au couvercle.

-

-

-

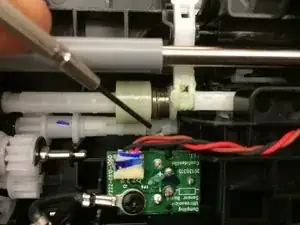

Retirez les rouleaux du côté intérieur du panneau (ceux qui sont recouverts de mousse, ils touchent le papier une fois le panneau fermé) et coincez un petit tournevis plat derrière l'extrémité du mauvais axe que vous pouvez voir de ce côté.

-

-

-

Gardez le tournevis en place pendant que vous appuyez simultanément sur le support dans lequel se trouvaient les rouleaux. Cela fera sortir le mauvais arbre de sa rainure. Cependant, vous ne pouvez le faire que lorsque l'arbre est tourné dans un sens particulier; sinon, il a des languettes qui le rendent trop large pour sortir de la rainure.

-

-

-

J'ai utilisé des pièces du vendeur eBay "g_loc". Ils sont interchangeables avec les pièces Epson. Ma solution a l'arbre intérieur Epson d'origine et l'arbre extérieur g_loc.

-

Vous pouvez également fixer la pièce Epson à l'aide de diverses méthodes : un trombone, une gaine thermorétractable, un petit ressort (comme celui d'un stylo), du ruban adhésif en aluminium, un mince ruban de fibre de verre imprégné de JB Weld, laisser sécher pendant la nuit, une courte longueur de tuyau en cuivre ou une paille en plastique.

-

Pour la fixation du trombone, à l'aide de pinces, enroulez fermement un trombone autour de l'arbre que vous avez retiré. Enveloppez-le près de l'extrémité qui n'est PAS évasée, puis tirez-le jusqu'à l'extrémité qui EST mauvaise, lorsque vous le déplacez vers le haut, il comprimera les extrémités évasées en place.

-

Soyez prudent si vous utilisez le fix de gaine thermorétractable. Je l'ai essayé et j'ai fait fondre la tige interne d'Epson en quelques secondes. La solution à ressort du stylo semble beaucoup plus sûre.

-

-

-

J'ai utilisé des capuchons en silicone (pour des punaises d'étagère de 5 mm de diamètre) comme celui présenté ici. Coupez l'extrémité fermée pour obtenir un capuchon de longueur ~ 0,75 cm et insérez-les sur les pièces en plastique au niveau des deux articulations. C'était un ajustement serré et sûr.

-

Insérez les longs composants en plastique du côté indiqué sur la deuxième image et fixez-les d'abord dans sa fente de l'autre côté avant de le pousser avec un tournevis plat et de l'insérer dans sa fente de ce côté indiqué sur l'image. Tout s'est bien passé après le correctif. Reste à savoir combien de temps cela va durer.

-

Un autre utilisateur, Eric Hargis, recommande comme autre alternative de mettre un vieux ressort dessus

-

Un autre utilisateur, lszablya, a recommandé une variante différente : "J'ai utilisé une gaine thermorétractable à double paroi. On dirait qu'elle a bien aspiré autour des broches."

-

-

-

L'affiche originale sur Amazon qui m'a inspiré à essayer cette solution (et si je pouvais trouver son nom, je lui donnerais crédit) recommandait de resserrer la pièce défectueuse avec une ficelle étroitement enroulée autour d'elle, puis de la calfeutrer pour empêcher la ficelle d'obtenir pris dans les choses, mais je doute qu'il tienne à long terme

-

-

-

Si vous êtes comme moi, vous vous demandez peut-être pourquoi ne pas simplement le coller sur l'arbre suivant en ligne. Eh bien, il doit en fait rencontrer cet arbre suivant à un angle en constante évolution, donc cela ne fonctionnera pas.

-

Pour remonter votre appareil, suivez ces instructions dans l'ordre inverse.

83 commentaires

I'm surprised no one else commented on this. Awesome article - worked perfectly. It's a bit tricky and I wouldn't recommend this for a rookie with tools, but it saved me. I couldn't find the part for this thing nor could I find a repair shop to work on it. It's funny how it started clicking 3 weeks out of warranty! THANKS FOR THE POST! and the effort. awesome!

Thank you so much for the detailed instructions. I found a replacement part on Amazon and together with that you've saved me hundreds of dollars.

thank you very much for posting this. was scratching my head for an hour, after reading your post, took 5 minutes to fix and get it going. what a relief. technical phone support was useless, troubleshooting was useless. scanner would have probably ended up in the trash if not for you. thank you!!!

Excellent advice - the safety pin worked a treat and doesn't even get stuck on the last page now- thank you so much! Strange how the first three comments on this are within a week apart - Our machine is just over two years - limited life span - but lives to scan another day now!

This fixed it for me. TYVM. Saved me 200.00, and did not even need to add a blank page.

Jim A -